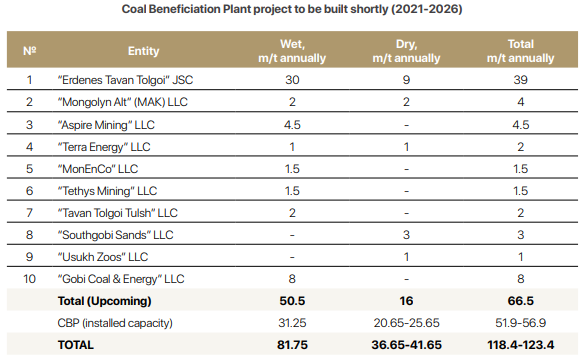

Mongolia's vision for sustainable economic development includes expanding the export of value-added mining products, a commitment that has led to plans for the establishment of a coal beneficiation plant. As of 2021, enriched coal made up just 6.6 percent of coal exports. However, by 2026, Mongolia aims to significantly enhance its coal beneficiation capacity, surpassing 121 million tonnes, with a significant portion of this capacity attributed to "Erdenes Tavan Tolgoi" JSC. The upcoming coal beneficiation plants will match the capacity of existing facilities. Notably, the wet beneficiation plant is set to contribute over 67 percent of the total beneficiation plant capacity. The remaining 30 percent will be distributed among several companies, including Erdenes Tavan Tolgoi JSC, Southgobi Sands LLC, Mongolyn Alt (MAK) LLC, Terra Energy LLC, and Usukh Zoos LLC. In contrast, the dry beneficiation plant's capacity will decrease compared to the constructed plant, signaling a shift towards expanding wet beneficiation capabilities in the future.

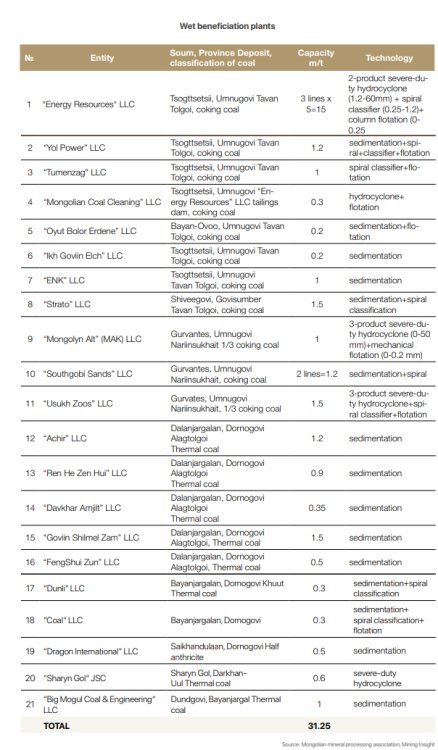

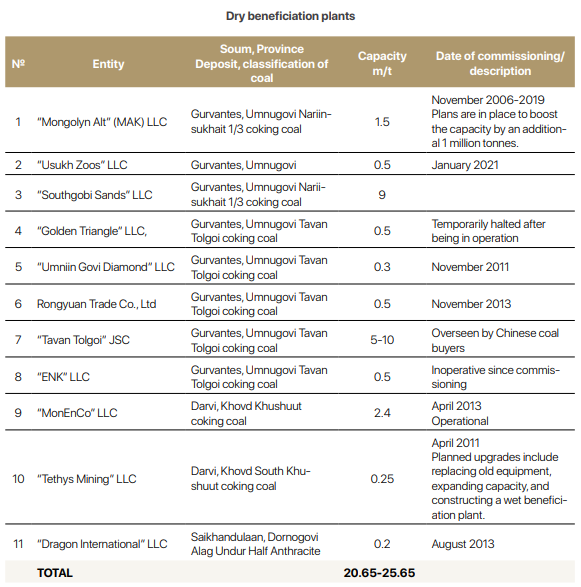

Mongolia currently hosts over 30 coal beneficiation facilities, including both dry and wet processing plants. Among the 11 dry coal beneficiation plants, some are looking to expand their capacity, while others have ceased operations. "MonEnCo" LLC has the capacity to extract 2.4 million tonnes of coal, as indicated by the feasibility study. However, it has been operating below its full capacity due to limitations at the border crossing. In the past year, the company exported 2.1 million tonnes of coal, marking the highest volume since its inception. The majority of coal processed by the 21 wet beneficiation plants consists of coking and thermal coal. Additionally, there is approximately of weak coking coal and half anthracite coal. The primary technology utilized in these concentrators is typically sedimentation, with more than half of the total plant employing a combination of sedimentation and related technologies. Certain plant capacities can be expanded, like Energy Resources LLC, which has a potential capacity of up to 25 million tonnes. Several smaller factories have also designed their facilities with the flexibility to increase their capacity.

Furthermore, there is a pressing need for a waste coal beneficiation plant to address the issue of coal waste in Mongolia's extensive coal mines. These mines accumulate substantial quantities of coal mixed with stones and ash, totaling between 2 to 4 million tonnes. Mongolian Coal Cleaning LLC, situated in Tsogttsetsii soum, Umnugovi Province, employs a wet beneficiation process to concentrate approximately 0.3 million tonnes of waste coal annually. Coal industry experts highlight that there is a niche for such smaller capacity plants. The electricity supply for wet beneficiation plants primarily relies on connections to the central power grid or diesel generators. Notably, factories in Dornogovi province are linked to the Choir power grid, while some companies source their electricity from proprietary sources or obtain it from the Sekhe port in China. Some coal beneficiation plants are operating below their full capacity, primarily due to constraints related to port capacities. This situation led to challenges such as the imposition of coal export quotas. However, since last year, these quotas have been lifted, and port operations have been extended to operate 24 hours a day, resulting in increased coal exports.

Another significant factor affecting this is the preference of buyers to purchase raw coal rather than processed coal, given that the main buyers of Mongolian coal are coal beneficiation plants. The capacity of wet concentrators has the potential to be boosted by 64 percent from its current capacity, reaching a total of 50.5 million tonnes. Achieving this expansion entails decisions regarding electricity and water supply, training concentrator engineers, studying past mistakes, and ensuring they are not repeated in new plants. Nevertheless, it is worth noting that representatives of coal concentrators consistently emphasize that challenges related to the royalties are the primary hindrance to realizing full operational capacity, capacity expansion, and the construction of new facilities. Engineers emphasize the necessity of processing coal through both dry and wet methods due to the anticipated increase in soil stripping as mining operations deepen. This expansion of mining activities is expected to lead to higher levels of toxic impurities and increased volatility in the coal. It is widely regarded as a more suitable approach to introduce dry concentrator technology in large mines facing water resource limitations. In contrast, in smaller mines with similar water constraints, the combination of crushing classification and dry concentrator technology is seen as a viable solution. The benefits of the dry concentration method include its reduced environmental impact, elimination of tailings concentration and the absence of chemical usage.

Mining Insight Magazine, December 2023